|

Other Useful Information |

|

|

|

|

|||

|

Family

Names |

|||

|

“Families”

of related consumables are identified with brand names which are briefly

described below. |

|||

|

Armet |

Armour welding electrode |

||

|

Chromet |

Chromium-molybdenum low alloy electrodes |

||

|

Cobstel |

Cobalt-base stellite type electrodes |

||

|

Cormet |

Chromium-molybdenum flux and metal cored wires |

||

|

Cupromet |

Copper and cupronickel electrodes |

||

|

HardCore |

Hardfacing cored wires |

||

|

KS |

Suffix for all-positional (generally basic)

electrodes with emphasis on pipework |

||

|

MetHard |

Hardfacing electrodes |

||

|

Metmax |

Stainless high recovery electrodes made on mild steel core wire |

||

|

Nimax |

Nickel-base high recovery electrodes made on nickel

core wire |

||

|

Nimrod |

Nickel-base electrodes |

||

|

Super R |

Stainless rutile electrodes (25.20 and 29.9

only) |

||

|

Supercore |

Stainless gas-shielded flux cored wires |

||

|

Supercore P |

All-positional stainless gas-shielded flux

cored wires |

||

|

Supermet |

Stainless (acid) rutile electrodes |

||

|

Supermig |

Stainless (high silicon) solid MIG wires |

||

|

Thermet |

High temperature austenitic electrodes |

||

|

Tufmet |

Low alloy electrodes for sub-zero toughness |

||

|

Ultramet |

Stainless rutile all-positional electrodes |

||

|

Ultramet B |

Stainless basic all-positional electrodes |

||

|

Ultramet P |

Fully positional (including vertical down) pipe

welding electrodes, suitable for root welding |

||

|

Vertamet |

Stainless (acid) rutile vertical down

electrodes |

||

|

WorkHard |

Hardfacing

electrodes with ability to work-harden |

||

|

Website The Metrode website contains a wealth of

information on the company and always contains the latest information and up to

date copies of all the data sheets |

|||

|

Welding

Positions |

|||||||||||||

|

Some welding engineers prefer to use the standard AWS/ASME terminology for welding positions – some use a general description – some use a mixture of both! |

|||||||||||||

|

It is useful in describing welding procedures if we all understand each other. This chart shows the basic AWS/ASME (and BS EN) welding positions, together with the outline descriptions. The AWS/ASME positions are described in ASME IX and the European terminology is used in BS EN 287-1 and defined in ISO 6947. |

|||||||||||||

|

ASME

(BS EN) Positions |

|||||||||||||

|

|

1G (PA) – downhand / gravity butt |

2G (PC) – horizontal-vertical butt |

|||||||||||

|

|

|

|

|

|

|||||||||

|

|

3G (PF) – vertical butt * |

4G (PE) – overhead butt |

5G (PF) – horizontal pipe butt |

||||||||||

|

|

|

|

|

||||||||||

|

|

6G (H-LO45) – inclined pipe butt |

1F (PA) – downhand or gravity fillet |

|||||||||||

|

|

|

|

|||||||||||

|

|

2F (PB) – standing fillet |

3F (PF) – vertical fillet * |

4F (PD) – overhead fillet |

||||||||||

|

|

|

|

|

||||||||||

|

|

|||||||||||||

|

* In BS EN terminology, vertical down fillet and butt joints are designated PG. |

|||||||||||||

|

|

|||||||||||||

|

Symbols

used on data sheets for welding positions – ASME (BS EN) |

|||||||||||||

|

|

Vertical up ASME 3G, 3F (PF) |

|

Vertical down (PG) |

|

Horizontal vertical ASME 2G (PC) |

||||||||

|

|

Overhead ASME 4G (PE, PD) |

|

Downhand / gravity ASME 1G, 1F (PA) |

|

Standing Fillet ASME 2F (PB) |

||||||||

|

Packaging and Storage |

|

|

|

The following shows the typical packaging used for the various processes with nominal dimensions taken from national standards (eg. BS EN ISO 544 and AWS). If packaging is critical then this should be confirmed at the time of order with our Customer Care Department. |

|

MMA / SMAW |

|

Standard MMA packaging is hermetically sealed metal tins with a ring-pull top; tin weights vary depending on product and diameter. There are three tins to a cardboard carton. |

|

The tins are hermetically sealed and meet the definition for hermetically sealed containers given in AWS A5.5. If unopened, and appropriately stored, this packaging will maintain the electrodes in the as-packed condition for an indefinite period of time. |

|

Electrodes can be used directly from the tin without the need for rebaking. Once opened the tins can be closed using the plastic lid supplied and should be stored at >18˚C and <60% relative humidity. Redrying requirements are given on the data sheets for individual electrodes. |

|

TIG / GTAW |

|

Standard packaging for cut TIG lengths is 2.5kg or 5kg plastic tubes. Superoot 316L flux cored TIG wire is packed in a 1kg plastic tube. |

|

TIG wires that may otherwise be susceptible to rusting (mild or low alloy steel) are copper coated. Under normal storage conditions TIG wires do not present any handling difficulties. |

|

MIG / GMAW |

|

Standard packaging for MIG wire is 15kg 300mm diameter spools, in a cardboard carton. Some wires are also available on 0.7kg 100mm diameter mini-spools or 5kg 200mm diameter midi-spools. Different spool types and dimensions are shown on the next page. |

|

MIG wires that may otherwise be susceptible to rusting (mild or low alloy steel) are copper coated. MIG spools should be properly handled and stored because any damage to spools can lead to feeding problems. |

|

Flux Cored Wire |

|

Standard packaging for flux cored wire is 12.5kg or 15kg 300mm diameter spools, vacuum sealed in barrier foil and in cardboard carton. Different spool types and dimensions are shown on the next page. |

|

As supplied wires are adequately protected from moisture pick-up but once opened part-used spools need to be correctly stored. It is recommended that spools are removed from machines overnight and put in a controlled store. If an opened spool is to be stored for any period of time it should be adequately protected (in a plastic bag with desiccant) and held in a controlled store. |

|

Submerged Arc Wire |

|

Standard packaging for submerged arc wire is 25kg coils in a cardboard carton. Different spool types and dimensions are shown on the next page. |

|

Submerged Arc Flux |

|

Standard packaging for flux is 20kg, 22.5kg or 25kg plastic bags in a sealed metal drum. |

|

For most applications it is recommended that the flux be dried prior to use. |

Storage and handling – further details

– click here

|

Standard Spool Sizes |

|

|

|

|

|

(1) Plastic spool |

(2) Wire basket |

|

|

|

|

|

|

|

(3) Wire spool - requiring adaptor |

(4) Submerged arc coil |

|

|

|

|

|

|

|

Type |

Code |

Nominal weight |

Outer diameter |

Inner diameter |

Outer width |

Bore diameter |

Pin hole |

|

|

|

|

kg |

d1 |

d2 |

b |

d3 |

d4 |

e1 |

|

Plastic - mini |

S100 |

0.7 |

100 |

- |

45 |

16.5 |

- |

- |

|

Plastic – midi |

S200 |

5 |

200 |

- |

55 |

50.5 |

10 |

44.5 |

|

Plastic |

S300 |

12.5/15 |

300 |

- |

103 |

50.5 |

10 |

44.5 |

|

Wire basket |

BS300 |

12.5/15 |

300 |

189 |

103 |

50.5 |

- |

- |

|

Wire spool (adaptor) |

B300 |

12.5/15 |

300 |

180 |

100 |

- |

- |

- |

|

Submerged arc |

R435 |

20/25 |

435 |

300 |

90 |

- |

- |

|

All measurements are in mm and are the nominal dimensions, for tolerances refer to international standards eg. BS EN ISO 544.

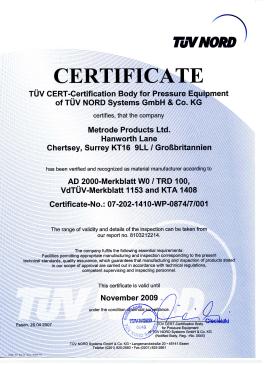

Quality – The Key to Customer

Confidence

·

The

first welding consumables manufacturer to attain BS5750, which became ISO 9001.

·

One

of LRQA’s first customers (cert. no. 840131)

·

Upgraded

to ISO 9001:2008

·

Extensive

record system with batch data going back to the companies foundation in 1963

How does our quality management

system affect you?

·

Our

main products are available direct from stock.

·

Your

views on our service are noted so that improvements can be made.

·

Complaints

are taken seriously and are dealt with promptly.

·

All

products are fully inspected before despatch.

·

All

batches are traceable to original manufacturing records.

·

All

deliveries are traceable to your order by the Test Certificate and/or Delivery

Note.

·

An

internal system to ensure that standard products with non-standard requirements

are correctly supplied.

|

Conversions |

|

|||||||

|

|

|||||||||

|

Approximate electrode size equivalents |

|||||||||

|

Diameter |

|||||||||

|

|

mm |

inch |

inch |

SWG |

|

||||

|

|

0.8 |

1/32 |

0.031 |

21 |

|

||||

|

|

0.9 |

- |

0.035 |

- |

|

||||

|

|

1.0 |

- |

0.039 |

19 |

|

||||

|

|

1.2 |

3/64 |

0.047 |

18 |

|

||||

|

|

1.6 |

1/16 |

0.063 |

16 |

|

||||

|

|

2.0 |

5/64 |

0.078 |

14 |

|

||||

|

|

2.4 |

3/32 |

0.094 |

12 |

|

||||

|

|

2.5 |

- |

0.098 |

- |

|

||||

|

|

3.0 |

- |

0.118 |

11 |

|

||||

|

|

3.2 |

1/8 |

0.125 |

10 |

|

||||

|

|

4.0 |

5/32 |

0.156 |

8 |

|

||||

|

|

5.0 |

3/16 |

0.188 |

6 |

|

||||

|

|

6.0 |

1/4 |

0.250 |

4 |

|

||||

|

|

|||||||||

|

Length

(not exact conversions but accepted

correlations between metric and imperial units for electrode lengths) |

|||||||||

|

|

mm |

inch |

|

|

|

||||

|

|

200 |

8 |

|

|

|

||||

|

|

230 |

9 |

|

|

|

||||

|

|

250 |

10 |

|

|

|

||||

|

|

300 |

12 |

|

|

|

||||

|

|

350 |

14 |

|

|

|

||||

|

|

380 |

15 |

|

|

|

||||

|

|

450 |

18 |

|

|

|

||||

|

|

|||||||||

|

Lengths of

TIG wire per kilogram * |

|||||||||

|

|

Diameter mm |

m/kg |

|

|

|

||||

|

|

0.8 |

260 |

|

|

|

||||

|

|

1.0 |

158 |

|

|

|||||

|

|

1.2 |

114 |

|

|

|||||

|

|

1.6 |

65 |

|

|

|||||

|

|

2.0 |

40 |

|

|

|||||

|

|

2.4 |

29 |

|

|

|||||

|

|

3.2 |

16 |

|

|

|||||

|

|

4.0 |

10 |

|

|

|||||

|

* Based on ferrous alloys with a density of ~8g/cm3 |

|||||||||

|

Note: 2.2mm diameter Superoot 316L has ~30 lengths per kg |

|||||||||

|

Approximate Hardness

Conversion (based on ASTM E140) |

|

|||||

|

|

|||||||

|

Rockwell B |

Rockwell C |

Vickers |

Brinell |

Products of approximately equivalent hardness |

|

|

|

55 |

- |

100 |

100 |

|

|

|

|

60 |

- |

107 |

107 |

|

|

|

|

65 |

- |

116 |

116 |

|

|

|

|

70 |

- |

125 |

125 |

|

|

|

|

75 |

- |

137 |

137 |

|

|

|

|

80 |

- |

150 |

150 |

CI Soft Flow Ni |

|

|

|

85 |

- |

165 |

165 |

Ultramild |

|

|

|

90 |

- |

185 |

185 |

CI Special Cast NiFe |

|

|

|

95 |

- |

210 |

210 |

308L, 316L, 307 (AW) |

|

|

|

100 |

~20 |

240 |

240 |

Nimrod/Nimax

C (AW), P91/P92 (PWHT) |

|

|

|

- |

22 |

248 |

237 |

625 (AW) |

|

|

|

- |

25 |

266 |

253 |

|

|

|

|

- |

28 |

286 |

271 |

Railrod, 29.9 Super R, duplex |

|

|

|

- |

30 |

302 |

286 |

Chromet 2 (AW), superduplex |

|

|

|

- |

35 |

345 |

327 |

410NiMo (AW) |

|

|

|

- |

40 |

392 |

371 |

Methard 350 |

|

|

|

- |

45 |

446 |

421 |

Cobstel 6, 625 (WH), 307 (WH),

P91/P92 (AW) |

|

|

|

- |

50 |

513 |

481 |

|

|

|

|

- |

55 |

595 |

560 |

Methard 650 |

|

|

|

- |

60 |

697 |

654 |

Methard 850 |

|

|

|

- |

62 |

746 |

688 |

Methard 750TS |

|

|

|

- |

65 |

832 |

- |

Methard 950, Methard

1050 |

|

|

|

- |

68 |

940 |

- |

|

|

|